By Sean Browne

From the May 2013 issue of Today’s Facility Manager

Regardless of whether the facility project at hand is an addition or the renovation of an existing space, selecting an appropriate ceiling system requires evaluation of a variety of factors. When selecting a ceiling, facility managers (fms) should begin with the considerations most important to the required performance in their buildings.

In many cases, visual criteria drive selection. And while visual criteria are key to the aesthetic needs of a space, it is the performance related criteria that are key to meeting the functional needs of the space.

In that regard, sound absorption and sound blocking are vital performance factors especially when dealing with commercial office space, healthcare, and educational facilities. With that in mind, there are some general guidelines fms can follow to ensure good acoustical performance in three types of spaces: closed plan, open plan, and exposed structure. It should also be noted that there are numerous options fms can implement to achieve both the desired visual and acoustical performance. There’s no need to choose between the two.

Closed Plan Spaces

In closed plan spaces, such as conference rooms and executive offices, the main function of ceilings is to limit the transmission of sound between adjacent spaces, especially when the spaces share a common ceiling plenum. Achieving speech privacy between spaces is the goal.

If partition walls go all the way up to the deck, fms should consider ceiling panels that have a Noise Reduction Coefficient (NRC) of 0.70 or higher. The NRC indicates the average percentage of sound that a ceiling absorbs. An NRC of 0.70 means the ceiling absorbs 70% of the sound that strikes it.

If partition walls only go up to the ceiling, and not to the deck, fms will want to select ceiling panels with an NRC of 0.60 to 0.70 and a Ceiling Attenuation Class (CAC) of 35 to 40. This combination of NRC and CAC provides speech privacy along with improved sound quality within the space. Fms should choose the lower ratings if sound masking is used; the higher ratings, if not used.

The CAC indicates the ability of a ceiling to block sound from penetrating a shared plenum and transmitting to an adjacent space. The higher the number, the better the ceiling performs as a barrier to sound.

Open Plan Spaces

In open plan spaces, the main function of the ceiling is to absorb sound that would normally bounce off surfaces and travel into nearby spaces or cubicles. To achieve sound control and reduce distractions, fms will want to choose ceiling panels featuring an NRC of 0.80 or higher and an Articulation Class (AC) of 170 or higher.

The AC indicates the ability of a ceiling to absorb sound in the human speech frequency range that passes over open plan dividers. The higher the AC, the better the ceiling performs as a sound absorber between open plan areas. For knowledge workers, choose an AC 200 or higher; for clerical workers, choose an AC 170 or higher.

Exposed Structure Spaces

Exposed structure spaces are those that have no ceiling and reveal building service elements such as ductwork and piping. This design style can exacerbate noise issues due to sound reflecting off the deck, resulting in excessive reverberation.

Any large space of this type will usually need some sound absorbing elements to help control noise and reverberation. In addition, if the exposed deck is less than 15′ high, reflections between open plan cubicles can cause distractions for occupants.

Noise issues related to exposed structure designs can be addressed with a number of different sound absorbing elements. Installing a low profile, discontinuous, high NRC system tight to the deck, for example, will maintain the exposed structure aesthetic while providing excellent sound absorption.

The system can be installed directly to an exposed deck (to maximize ceiling height), onto drywall, or suspended with wires. For example, if panels with an NRC of 0.90 are installed over only 20% of an exposed deck space, it can reduce reverberation up to 50%.

“Free Floating” Options

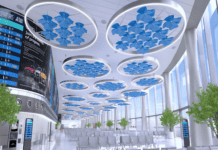

Acoustical clouds, canopies, baffles, and blades—four types of “free floating” ceilings—are another way of adding sound absorption in an open plenum space while allowing for the exposed look. Each of these options absorbs sound on both front and back surfaces. As a result, these actually provide greater sound absorption than a continuous ceiling of the same surface area.

Acoustical clouds suspended above work areas provide a type of interrupted ceiling plane. As such, they help control both reflections between cubicles and distant reverberation, reducing occupant annoyance and distractions.

Acoustical canopies also reduce noise and reverberation in the space below them, but are different in size and appearance compared to acoustical clouds. Visually, clouds are flat, while canopies are curved and can be installed as hills or valleys. Meanwhile, baffles and blades are suspended vertically creating an interesting visual and provide substantial sound absorption.

Replacement And Disposal

Regardless of the type of space, at some point fms need to replace the ceiling panels in their facilities. Damage from water stains, even from a small intermittent source, can ruin panels. Dirt accumulation—perhaps from air diffusers—is another common cause for replacement. Panel damage not only detracts from appearance but can also cause a reduction in light reflectance and acoustic efficiency.

Replacing ceiling panels is relatively easy through a ceiling distributor. To replace damaged panels, fms need to remove a damaged panel to access the manufacturer, panel name, and item number on the back side. Using that information, a distributor can assist fms in obtaining the proper replacements.

Finally, when an acoustical ceiling is at the end of its useful life, fms should consider recycling the materials—rather than disposing of them in a way where they will end up in a landfill. The first ceiling recycling program in the industry was introduced in 1999, and it enables fms to ship ceilings from renovation projects to a ceilings plant as an alternative to landfill disposal. The discarded ceilings are then used to manufacture new ceilings.

Ceiling panels removed from a space are either stacked on a pallet and wrapped for delivery to the ceilings plant, or dumped into a roll-off container and collected by a construction and demolition processor that will bale the tiles for delivery.

Since this program began, more than 123 million square feet of ceiling panels have been recycled. That’s equal to 16,000 roll-off containers full of construction debris that would have normally been taken to landfills.

Browne is principal scientist, global acoustics for Armstrong Commercial Ceiling Systems.

![[VIDEO] Collect Asset Data at the Speed of Walking a Building](https://facilityexecutive.com/wp-content/uploads/2024/02/maxresdefault-324x160.jpg)